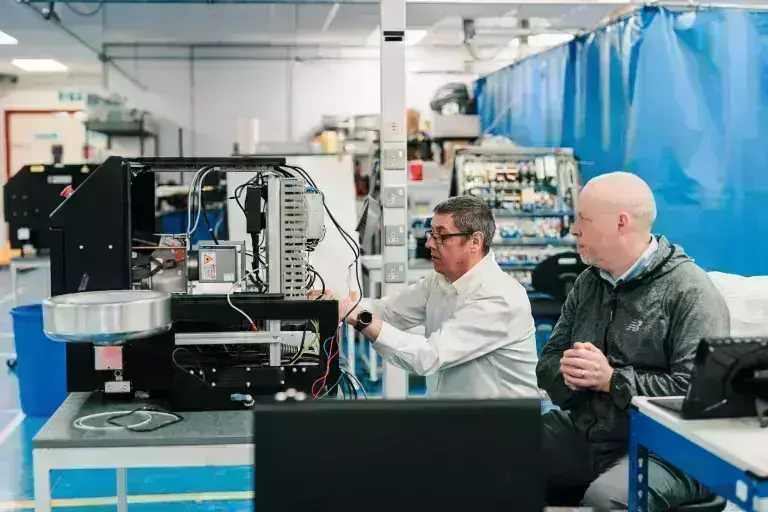

From the highest volume production to lower volume production and maintenance and overhaul, whatever your application, there is a Nova laser wire marker designed to meet your needs.

- Low volume production & MRO work: N50-100i series

- Intermediate applications: Nova 820i & Nova 840i

- High volume production: Nova 860i & Nova 880i

Produced originally for the aircraft industry CAPRIS and Nova laser wire markers also have application to harness production for space systems, rail cars, military and specialist ground vehicles, yellow goods (construction and earth moving equipment) and other transportation, control systems and electrical products.

UV laser wire marking technology has been developed to meet the need for safe, non-damaging, permanent identification coding of high performance PTFE/Teflon® and other “non-stick” wire insulation materials, particularly to meet the requirements of the aerospace and defence industry.

How does laser wire marking work and how could a Nova non-contact laser wire marker benefit your wire harness operation? Read more about laser wire marking technology.

Nova™ is a trademark of Spectrum Technologies

If you want to talk with us directly about a product, please contact us, and we will get back to you soon.

AVAILABLE MODELS